reduce crane time

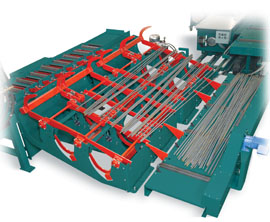

The EvacuBin material handling system reduces crane lifts and streamlines rebar processing by acumulating bundles meant for bending.

The EvacuBin system accumulates cut bundles from the shearline in designated pockets. Each pocket can be independently emptied, allowing for optimized sorting and discharge at the operator's control. An integrated LiftRoll conveyor automatically elevates bundles to the appropriate transfer height, eliminating the need for costly elevated platforms or manual lifting.

Increased Efficiency:

Eliminate the need to bend bars in cutting order, allowing for continuous shearing and significantly faster processing.

Reduced Man Hours:

Minimize labor costs associated with moving bundles with cranes or fork lift

Enhanced Flexibility:

Sort and discharge rebar bundles on demand, maximizing flexibility for downstream operations.